Anping MamBa Screen Mesh MFG.,Co.Ltd alan@mbascreen.com 86-311-86250130

Product Details

Place of Origin: HeBei,China

Brand Name: MaMBa

Certification: CE

Model Number: Mine Sieving Mesh

Payment & Shipping Terms

Minimum Order Quantity: 1500 Square Meter/Square Meters per Week

Price: $39.50/square meters

Packaging Details: Outside use wooden crates or plywood pallets.

Delivery Time: 30

Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability: |

1500 Square Meter/Square Meters Per Week |

Product Name: |

High Tensile 65mn Mn Steel Wire Woven Mesh Shaker Gravel Mining Vibrating Screen Price For Sale |

Weave Style: |

Plain Weave, Dutch Weave, Plain/Twill/Dutch Weave, Dutc/plain/twill Weave, Twill Or Dutch |

Application: |

Screening, Filtering Printing Etc.. |

Material: |

SS304 316 410 430 310 904L Etc.. |

Type: |

Weave Wire Mesh |

Wire Diameter: |

0.5-8mm, 0.02-2mm, Requirement, 0.9mm, 0.02-5.00mm |

Feature: |

Corrosion Resistance |

Hook: |

60-180 Degree, C Hook Available. |

Hole Shape: |

Square |

Supply Ability: |

1500 Square Meter/Square Meters Per Week |

Product Name: |

High Tensile 65mn Mn Steel Wire Woven Mesh Shaker Gravel Mining Vibrating Screen Price For Sale |

Weave Style: |

Plain Weave, Dutch Weave, Plain/Twill/Dutch Weave, Dutc/plain/twill Weave, Twill Or Dutch |

Application: |

Screening, Filtering Printing Etc.. |

Material: |

SS304 316 410 430 310 904L Etc.. |

Type: |

Weave Wire Mesh |

Wire Diameter: |

0.5-8mm, 0.02-2mm, Requirement, 0.9mm, 0.02-5.00mm |

Feature: |

Corrosion Resistance |

Hook: |

60-180 Degree, C Hook Available. |

Hole Shape: |

Square |

Woven Vibrating Filter Screen Mesh with Hook Crimped Wire Mesh for Mining

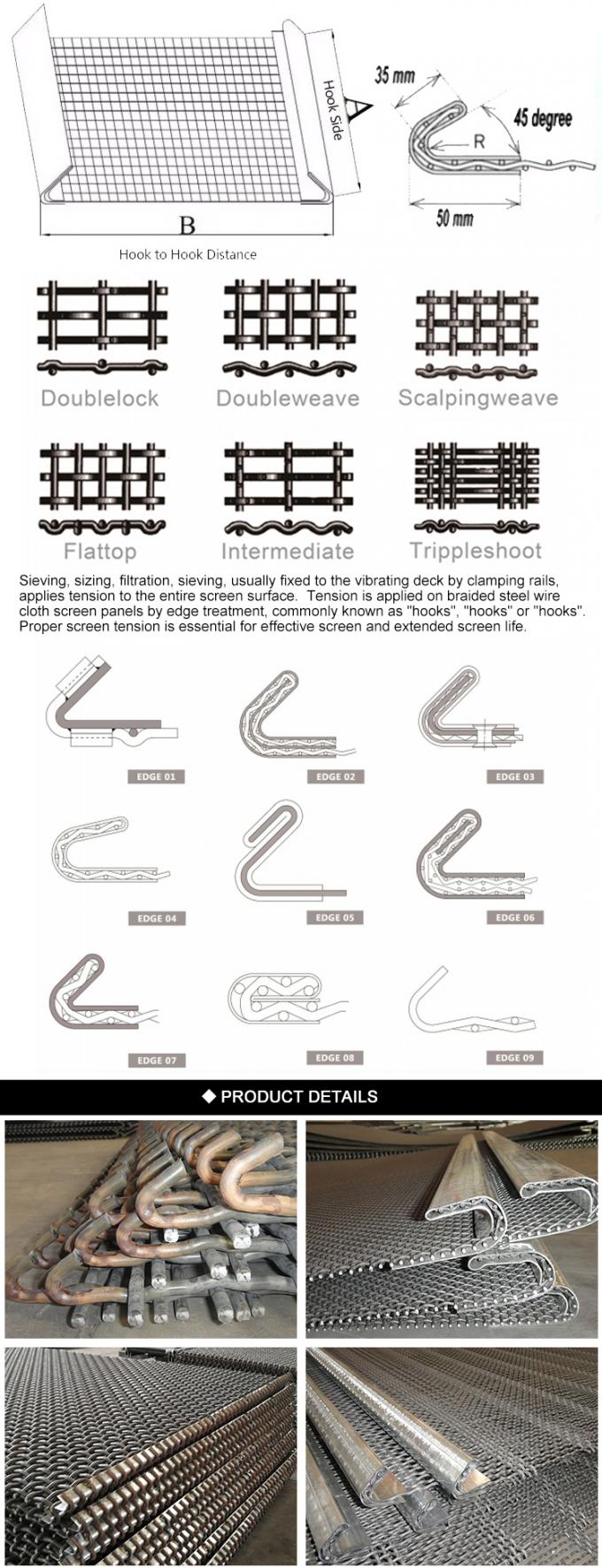

| SPECIFICATIONS FOR MINE SCREEN MESH | |||

| treatment for screen side | wire diameter | mesh size | wide X length |

| plain | 0.8-22mm | 1-150mm |

wide:0.5-4m length:1-30m |

| with hook | 2.0-22mm | 3-150mm |

wide:0.5-4m length:1-6m |

| with hook metal plate | 2-22mm | 3-150mm |

wide:0.5-3m length:1-3m |

Woven wire screens are widely used in various industries for the purpose of screening and filtering materials. These screens are typically made by weaving metal wires together to form a mesh pattern. The woven wire mesh can be constructed in different weave patterns, such as plain weave, twill weave, or Dutch weave, depending on the specific requirements of the application.

Here are some key aspects of woven wire screens:

Material: Woven wire screens are commonly made from materials like stainless steel, high-carbon steel, or other alloys. The material choice depends on factors such as corrosion resistance, strength, and the nature of the materials being screened.

Weave Patterns:

Mesh Size: The mesh size or opening size of the woven wire screen is crucial and is determined by the application requirements. Fine meshes are used for precise filtration, while coarser meshes are used for larger particles.

Applications:

Durability: Woven wire screens are known for their durability and resistance to wear and tear, making them suitable for demanding industrial applications.

Customization: Manufacturers can produce woven wire screens in custom sizes and specifications based on the specific needs of the customer or application.

Maintenance: Depending on the material used, woven wire screens can be relatively easy to clean and maintain, contributing to their longevity and efficiency.

Material:

highly abrasion-resistant spring steel wire or stainless spring steel wire.

| No | Grade | Chemical Composition | ||

| C | Si | Mn | ||

| 1 | 45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 |

| 2 | 50 | 0.47-0.55 | ||

| 3 | 55 | 0.52-0.60 | ||

| 4 | 60 | 0.57-0.65 | ||

| 5 | 65 | 0.62-0.70 | ||

| 6 | 70 | 0.67-0.75 | ||

| 7 | 65Mn | 0.62-0.70 | 0.90-1.20 | |

| 8 | 72A | 0.70-0.75 | 0.15-0.35 | 0.30-0.60 |

| No | Grade | Chemical Composition | |||

| C | Ni | Mn | Cr | ||

| 1 | 304 | ≤0.08 | 8.0-11.0 | ≤2 | 18.0-20.0 |

| 2 | 321 | ≤0.08 | 9.0-12.0 | ≤2 | 17.0-19.0 |

| 3 | 316 | ≤0.08 | 10.0-14.0 | ≤2 | 16.0-18.5 |

| 4 | 2205 | ≤0.03 | 4.5-6.5 | 2.5-3.5 | 21.0-24.0 |

| 5 | 2507 | ≤0.03 | 6-8 | ≤1.2 | 24-26 |

Features:

Easy to Install

Lower Cost

Higher screening accuracy

Require less maintenance

Sturdy construction

| Material | Manganese stee(65Mn,30Mn)l,high carbon steel(72a,82b,60,55,45),spring steel,stainless steel(316,304,202). |

| Wire Diameter | 0.5mm to 22mm |

| Mesh Size | 1mm to 150mm |

| Width | Can be required |

| Length | Can be required |

| Advantage |

The manganese steel is very abrasive and corrosive. And the stainless steel material is very corrosive.According to the different application, also choose different materials.Crimped wire offers stable structure and good strength. |

| Packaging | 1.inside:plastic films 2.outside:bag 3.within wood tray or iron tray, wood box |

1.Professional production equipment, machine gear, product mesh precision

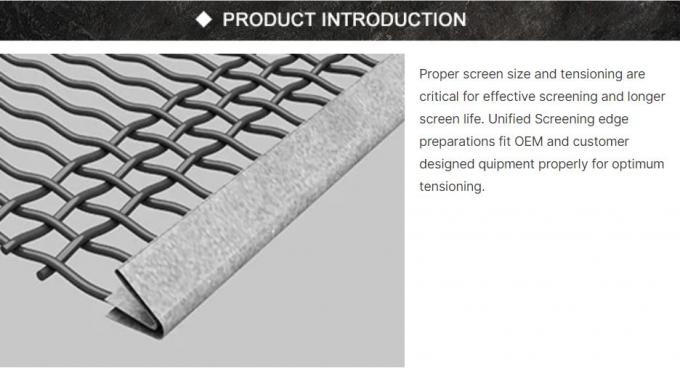

Installation instructions:

the screen is installed with using of tension metallic bars into a separator over different types of hook strips, further with using of side bars and wedges, possibly is fastened into a frame.

Application:

applies to vibrating screens for primary sieving of mine and aggregates, as well as asphalt mixer plant in road building.