Anping MamBa Screen Mesh MFG.,Co.Ltd alan@mbascreen.com 86-311-86250130

Product Details

Place of Origin: China

Brand Name: Mam Ba

Certification: ISO9001,SGS Test

Model Number: PU

Payment & Shipping Terms

Minimum Order Quantity: 10 Square Meter

Price: negotiable

Packaging Details: Put into Carton or on Pallet

Delivery Time: 10-20days

Payment Terms: L/C, T/T, Western Union, MoneyGram, D/A, D/P,O/A,CAD.

Supply Ability: 10000 Square Meter/Week

Name: |

Polyurethane Tension Mats |

Material: |

MDI Or TDI Polyurethane |

Color: |

Yellow, Red, Green Or Customizable |

Hardness: |

80A-95A |

Modular Normal Sizes: |

305*305*30MM,610*305*30MM |

Application: |

Qarry, Coal,Mining Industrial |

Feature: |

High Wear Resistance,More Durable |

Operating Temperature: |

Below 80ºC |

Install Stype: |

Rail Support,Pin&Sleeve Or Trim Strip, Bolt,Clamp |

Standard: |

ISO9001,SGS Test |

Warranty: |

3-6months |

Aperture Sizes: |

0.12-120mm |

Screening Thickness: |

7-60mm |

Aperture Shape: |

Square, Rectangle,or As Your Requirement |

Name: |

Polyurethane Tension Mats |

Material: |

MDI Or TDI Polyurethane |

Color: |

Yellow, Red, Green Or Customizable |

Hardness: |

80A-95A |

Modular Normal Sizes: |

305*305*30MM,610*305*30MM |

Application: |

Qarry, Coal,Mining Industrial |

Feature: |

High Wear Resistance,More Durable |

Operating Temperature: |

Below 80ºC |

Install Stype: |

Rail Support,Pin&Sleeve Or Trim Strip, Bolt,Clamp |

Standard: |

ISO9001,SGS Test |

Warranty: |

3-6months |

Aperture Sizes: |

0.12-120mm |

Screening Thickness: |

7-60mm |

Aperture Shape: |

Square, Rectangle,or As Your Requirement |

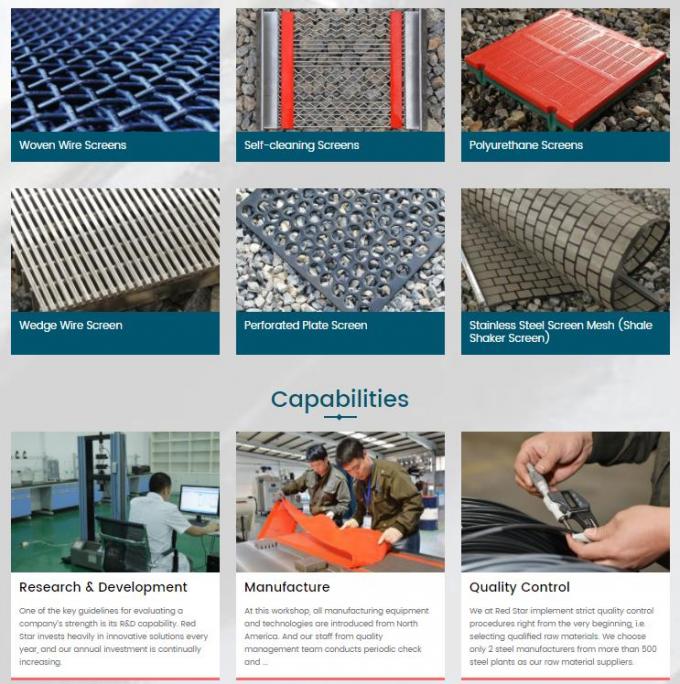

Achieve optimum performance in your operation and reduce downtime with Mamba Polyurethane Tension Mats. Expert engineering has gone into making sure they last longer and offer greater accuracy.

Our polyurethane tension mats have been specially designed to reduce pegging and blinding and to help you avoid unplanned downtime.

Customized for your application

We spent years researching and developing our mats so that we can offer design customization for applications. Now you can be sure that your mat was built with the precise relief angle that is best suited for your operation. With our high quality manufacturing processes to back the unique designs, the accuracy and reliability of your mat will minimize the risk of begging and blinding to reduce the frequency of screen failure.

Common applications

Mamba Polyurethane Tension Mats come in a range of designs and can be as customized as your specifications require. They are especially suited to scalping, mineral processing and aggregate processing.

The mats have a long life when screening materials such as:

1.Quartz

2.Silicon

3.Sand

4.Gravel

Polyurethane mats offer the same elasticity as rubber mats but allow for much greater accuracy and are more resistant to wear. The result is more precise screening and a longer lasting mat. Our newest grade of polyurethane media was developed as we partnered with a trusted prepolymer supplier to combine the physical properties of rubber and polyurethane elastomers. This new addition to our offered materials has been proven in the field to be tough and long lasting even under harsh operating conditions.

As a leading supplier of mineral processing equipment, we have many years of experience with the advantages and limitations of each grade of polyurethane so that we can provide media recommendations that are as customised as your processes.

Factors affecting screening media selection

1.Mineral type, size, physical characteristics and chemical properties

2.Operating conditions

3.Throughput

4.Optimum screening efficiency

5.Optimum open area for maximum efficiency and throughput

6.Target wear life

7.Cost effectiveness

8.Mat media design in relation to mass, securing system and apertures

Polyurethane Mats Specification:

| Material | polyurethane(MDI,TDI) |

| Screening Thickness | 7-60mm |

| Total Screen Panel Thickness | 10-60mm |

| Open area rate | 25%-60% |

| Aperture size | 0.12-100/120mm |

| Hardness | 85-95A |

| Color | Yellow, Red, Green |

Following years of work through our research and development program, we can ensure our mats are designed and built with the correct relief angle to suit each application – a promise that is backed by our high-quality manufacturing processes. The accuracy and reliability of these mats will minimise the risk of pegging and blinding and reduce the frequency of stoppages due to screen failures.

Best suited to:

Produced in a range of designs, Mamba Polyurethane Tension Mats can be customised to suit your needs. They are especially suited to scalping, mineral processing and aggregate processing.

Modular and Tensioned Polyurethane Screen Panel Applications:

Tensioned polyurethane screen is fitted to all vibrating screens

;

Separate and screen almost all of materials from coarse stones to fine materials;

Ideal for both dry and wet materials.

The polyurethane screen is a substitute screening material for metal mesh in mining mineral processing, grading, dehydration and other machines. Featuring age resistance and wear resistance.