Anping MamBa Screen Mesh MFG.,Co.Ltd alan@mbascreen.com 86-311-86250130

Product Details

Place of Origin: China

Brand Name: Mam Ba

Certification: ISO9001,SGS Test

Model Number: PU

Payment & Shipping Terms

Minimum Order Quantity: 10 Square Meter

Price: negotiable

Packaging Details: Put into Carton or on Pallet

Delivery Time: 10-20days

Payment Terms: L/C, T/T, Western Union, MoneyGram, D/A, D/P,O/A,CAD.

Supply Ability: 10000 Square Meter/Week

Name: |

Polyurethane Tensioned Screens |

Material: |

MDI Or TDI Polyurethane |

Color: |

Yellow, Red, Green Or Customizable |

Hardness: |

80A-95A |

Modular Normal Sizes: |

305*305*30MM,610*305*30MM |

Application: |

Qarry, Coal,Mining Industrial |

Feature: |

High Wear Resistance,More Durable |

Operating Temperature: |

Below 80ºC |

Install Stype: |

Rail Support,Pin&Sleeve Or Trim Strip, Bolt,Clamp |

Standard: |

ISO9001,SGS Test |

Warranty: |

3-6months |

Aperture Sizes: |

0.12-120mm |

Screening Thickness: |

7-60mm |

Aperture Shape: |

Square, Rectangle,or As Your Requirement |

Name: |

Polyurethane Tensioned Screens |

Material: |

MDI Or TDI Polyurethane |

Color: |

Yellow, Red, Green Or Customizable |

Hardness: |

80A-95A |

Modular Normal Sizes: |

305*305*30MM,610*305*30MM |

Application: |

Qarry, Coal,Mining Industrial |

Feature: |

High Wear Resistance,More Durable |

Operating Temperature: |

Below 80ºC |

Install Stype: |

Rail Support,Pin&Sleeve Or Trim Strip, Bolt,Clamp |

Standard: |

ISO9001,SGS Test |

Warranty: |

3-6months |

Aperture Sizes: |

0.12-120mm |

Screening Thickness: |

7-60mm |

Aperture Shape: |

Square, Rectangle,or As Your Requirement |

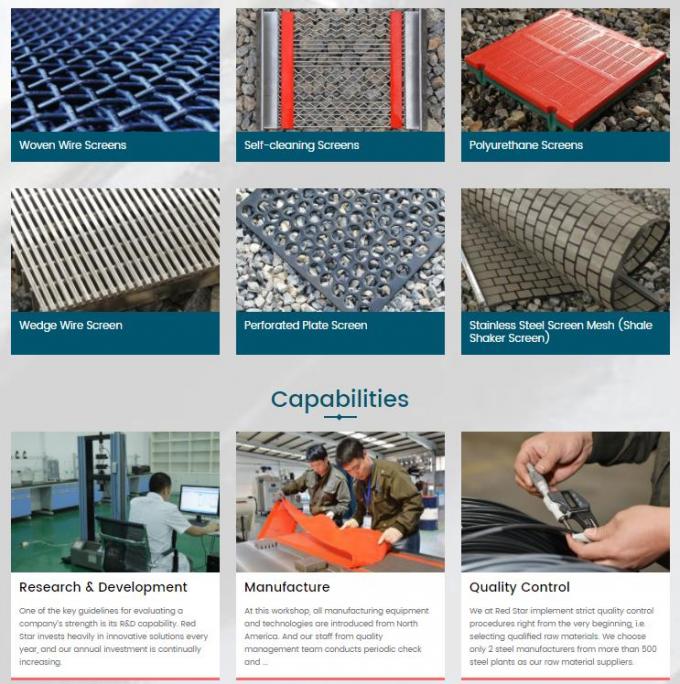

Customizable Sizes Polyurethane Tensioned Screens for Dehydration and Separating

Mamba’s polyurethane screens are manufactured using open-cast process which provides wear life of 1.5 to 2 times longer than that found in injection-molded polyurethane screen. Although open-cast production method is more labor-intensive, but it results in superior wear life performance and minimal maintenance cost, primarily due to the long slow curing process which enhances the cross-linking of the polyurethane molecules.

All raw materials and manufacturing equipment for Mamba’s polyurethane screens are sourced from Europe, and our quality control is certified in accordance with ISO quality management system, allowing us to provide consistent top quality polyurethane screening products.

Mamba’s polyurethane tensioned screen panels represent the best screening solution for those applications requiring both elevated screening performance and high wear resistance in every brand and model of vibrating screen.

In fact our manufacturing system and the extraordinary technological characteristics of our polyurethane materials make them the most performing tool for coarse, medium and fine screening.Every application is analysed to understand the technical scenario in detail.

The analysis is used to study a customized product where several factors are considered:

· Polyurethane type - traditional or elastic

· Polyurethane hardness

· Screen panel dimensions

· Aperture shape and size to obtain the desired cut size

· Perforation (punching or Water-Jet) or moulding method

· Reinforcing layers (Rubber, Steel, fabric…)

Every stage of screening - from to gross to fine – can take advantage of our tensioned screen panels thanks to the customized design of our products

Modular Screens

Efficient fitting

The fast fitting and demounting of our handy screen components reduces downtimes and enables only the actually worn part of a screen fitting to be changed.

Available hole widths

There are several hundred different hole widths in different hole shapes available for polyurethane screens. At present we can manufacture slit perforations from 0.12 x 5.6 mm up to 15 x 120 mm and square perforations from 0.8 mm up to 150 mm.

Application-specific series

The demands made of a screen panel vary considerably according to application: if you need an extremely large screen area, choose our HE (high efficiency) series; standard is the RG (regular) series, while our LL (long-life) series is exceptionally robust.We offer the optimum screen for every purpose –often different series are combined on a screening machine

Available material hardnesses

Depending on the material to be screened and the parameters of the screening machine, softer screens help securely prevent clogging with terminal grains. For this we offer our polyurethanes with the following degrees of hardness in the perforated areas: 35, 45, 65 or 85 Shore A

Highly wear-resistant

Mamba uses only polyurethanes with the best possible wear-resistant properties by brand manufacturers. A refined production system enables precise and economic production.

Noise-damping

The noise-damping properties of polyurethane reduce noise emission. Official requirements with regard to environmental and occupational safety and health can therefore be met more easily.

Temperature resistance

Polyurethanes can normally be used at temperatures of up to approx. 80 °C. We offer special products that can be used up to a sieved material temperature of 120 °C and even up to160 °C.

Modular and Tensioned Polyurethane Screen Panel Material:

Polyurethane is a new type of polymer composite material, with nature between plastic and rubber while performance superior over the two materials. Polyurethane screen is lightweight and easy to install in screening situations where material specifications are frequently changed.

The polyurethane mesh is ideal for all screening applications where screening efficiency and noise reduction is crucial.

The various opening sizes ensure the high separating and screening efficiency and the smooth surface and polyurethane materials make the screen has much lower noise than the woven vibrating screen mesh or perforated vibrating screen mesh.

Modular and Tensioned Polyurethane Screen Panel Popular Sizes:

· Material: polyurethane material and steel frame and Steel Wire Skeleton

· Thickness: 15mm - 60mm.

· Hole type: square, rectangular, round and other types are available.

· Hole size: 2.5mm - 120mm.

· Panel width: max. 2m.

· Panel length: max. 3m.

· Hook type: metal or polyurethane.

· Hook direction: transverse or longitudinal.

· Color: red, yellow, blue and any other colors.

Modular and Tensioned Polyurethane Screen Panel Applications:

Tensioned polyurethane screen is fitted to all vibrating screens

;

Separate and screen almost all of materials from coarse stones to fine materials;

Ideal for both dry and wet materials.

The polyurethane screen is a substitute screening material for metal mesh in mining mineral processing, grading, dehydration and other machines. Featuring age resistance and wear resistance.