Anping MamBa Screen Mesh MFG.,Co.Ltd alan@mbascreen.com 86-311-86250130

Product Details

Place of Origin: China

Brand Name: Mam Ba

Certification: ISO

Model Number: 004

Payment & Shipping Terms

Minimum Order Quantity: 10pcs; Generally any qty is available, just cost is different.

Price: negotiable

Packaging Details: Iron tube or wooden box

Delivery Time: within 15days after confirmation

Payment Terms: L/C, D/A, D/P, T/T, Western Union

Supply Ability: 80pcs per day

Material: |

Polyurethane |

Thickness: |

20-60mm |

Opening: |

0.6-160mm |

Type: |

Panle, Hooked |

Hole Type: |

Comb, Square, Oblong, Round |

Usage: |

Vibrating, Screening, Filtering |

Certificate: |

ISO |

Market: |

America, Africa, Australia, Some Of Europen Countries |

Product: |

Flip Flow Screen |

Daily Output: |

100pcs |

Material: |

Polyurethane |

Thickness: |

20-60mm |

Opening: |

0.6-160mm |

Type: |

Panle, Hooked |

Hole Type: |

Comb, Square, Oblong, Round |

Usage: |

Vibrating, Screening, Filtering |

Certificate: |

ISO |

Market: |

America, Africa, Australia, Some Of Europen Countries |

Product: |

Flip Flow Screen |

Daily Output: |

100pcs |

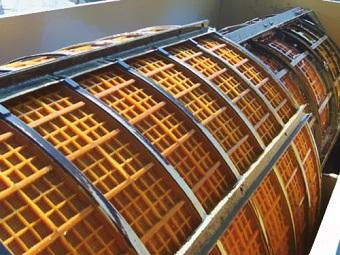

PU Polyurethane Flip Flow Screens Screen for Mining Quarrying Industry

Flip-Flow Vibrating Screens remove fines out of wet, sticky or generally difficult to handle materials. Materials processed using a Flip-Flow Vibrating Screen typically cannot be screened using other technologies, such as rotary screens, conventional vibrating screens, etc. Applications where the screen might be used include municipal solid waste, tire recycling, construction & demolition waste, glass recycling, biomass, metals, food recycling, drug recycling, used car recycling, slags from incineration, oil and sludge, etc.

Screens are made of high density polyurethane panels. Each panel is fixed to both the main frame and the sub-resonant frame. By amplifying the vibration of the main frame of the screen in the sub-resonant frame and due to the polyurethane panels being fixed to both frames, screen panels bump together creating the “flip-flow” motion. This ensures that screened material will not stick or get caught in the screen.

WHY FLIP-FLOW?

Self-cleaning Designed with maximum open area for optimum screening Manufactured from polyurethane for maximum wear life and resistance to constant flexing Supplied with square or slotted apertures to suit your application Pre-punched with holes to suit your fixing bolts/ studs.

BENEFITS

Non blinding screening mats – less contamination Compact and modular construction Single or multi-deck execution Dynamic wear resistant screening mats allow an efficient material flow – screwless mounted (fast changeover). The high acceleration on the screening mats ensures a self-cleaning effect. Infinite adjustment of the vibrating parameters to match changing product characteristics / qualities Low operating and maintenance costs.

Anping Mam Ba Wire Mesh MFG Company, which is founded in 1989, has been devoted into wire cloth and screen media production for 26 years. The company owns 18 patented products, all of them have been up to EU, GB and ASTM standards. The company has acquired certificates of ISO 14001 Environmental Management System, ISO 9001 Quality Management System and OHSAS 18001 Occupation Health Safety Management System.

Mam Ba Wire Mesh MFG Company has a set of strict procedures to control the quality from materials to final products shipping. Our woven wire cloth has been widely accepted by clients from North America, Australia, Europe and Middle East for its high durability, precision and impact resistance. 90% of our products are used in international markets because they can be perfectly matched with various kinds of vibrating screens including international brands. For all of mining, aggregate, asphalt mixing and road construction industries, every cent saved from high quality production, fast parts changes and a longer part wearlife will be eventually converted into hard profits and real cost reduction of companies. As the most important part of vibrating screens, a set of high-quality wire cloth with high accuracy, long wear life and high anti-impact is the foundation of production quality assurance in all industries above.